Design Improvements for the Zenith 601 HDS:

Fairing of Nose Gear

Fairing of Nose Gear

Any round tube exposed to the slipstream produces an amazing amount

of drag. Thus, fairing the relatively long nose gear tube seems

a good idea. Also, if the nose gear tube has no fairing, then it becomes

covered with dust and grit, and the substantial up-and-down

movement of the nose gear during taxiing, takeoff, and landing

grinds down the Delrin bearing.

The fairing consists of two fitted pieces. Each is held together

at the rear lip by a vertical wire inserted into a piano hinge.

A spring loaded tube pushes

the upper fairing against the nose gear bearing. The lower piece is

held in place by a small tube welded into the nose gear. That tube

is used by a lightweight tow bar that inserts a long AN3 bolt into the

tube. The shiny surface is stainless steel tape

on top of the aluminum of the lower fairing part.

The same tape is used inside

the upper fairing part, so there is no wear. Once a year the

fairing is removed, and the nose gear tube is cleaned and lightly

coated with grease. This has essentially stopped the wear of the

Delrin bearing of the nose gear.

Optimal fairing would require that the width of the fairing is

three times the diameter of the nose gear tube. This is not possible here

since the turning of the nose gear and the channel bracket holding

the lower nose gear bearing limit the width.

An alternate tow bar attachment is a follows.

One drills a 3/16 hole into the nose gear tube, inserts an

AN3 bolt with two spacers on the two sides, and keeps the bolt in place

with a nylon stop nut. Sealant is used to prevent moisture from

entering the gear tube. The tow bar is clamped to the spacers.

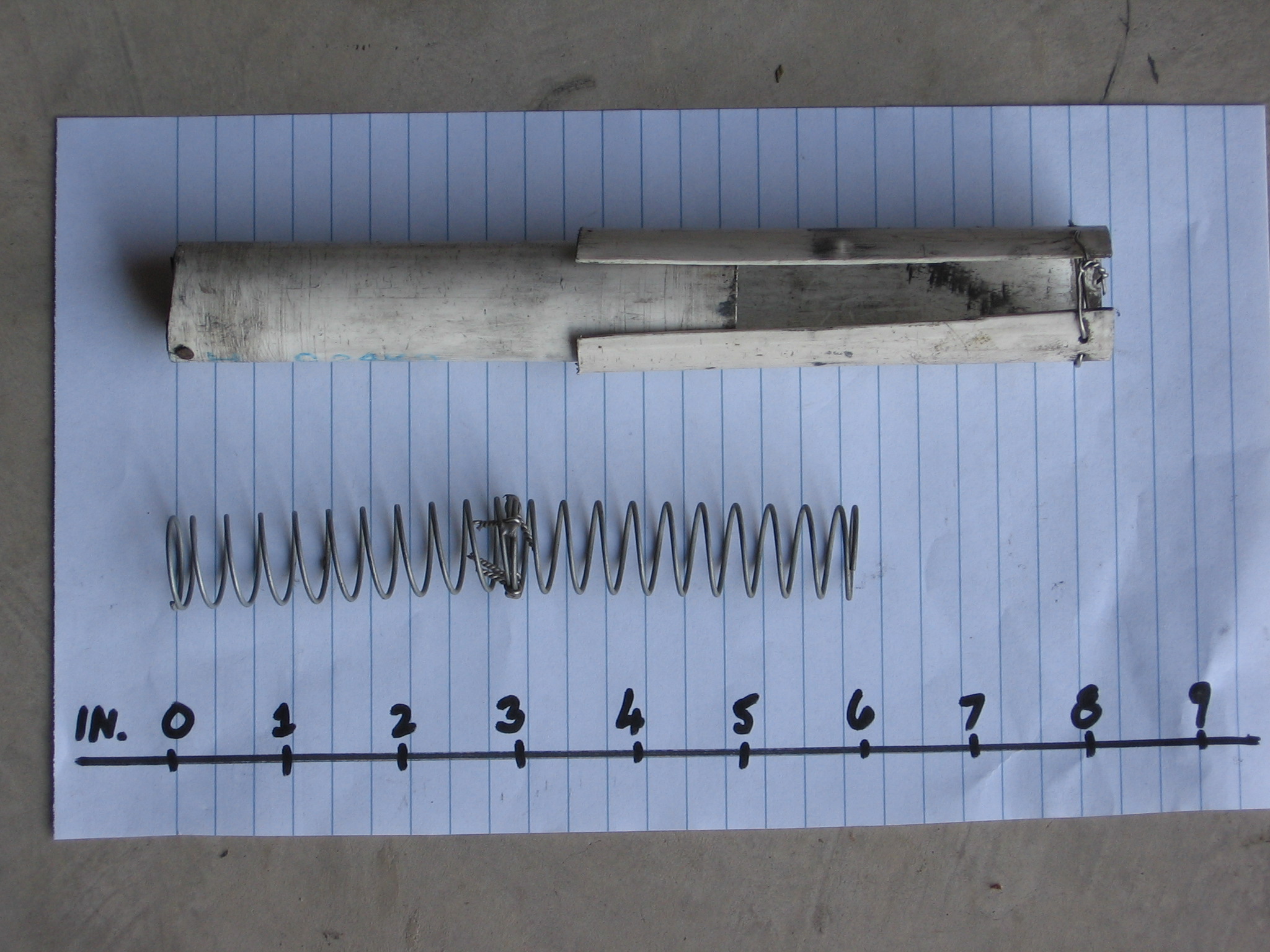

Here are details of the fairing. First a picture of the two nested

tubes and the spring. The tubes are made from thin-wall PVC tubing.

To get proper nesting, the outer tube was cut and widened in hot water.

Each tube has a stop at the end.

The spring is inserted into the tubes and thus pushes them apart.

We could not get a soft spring of correct size and made it from two springs.

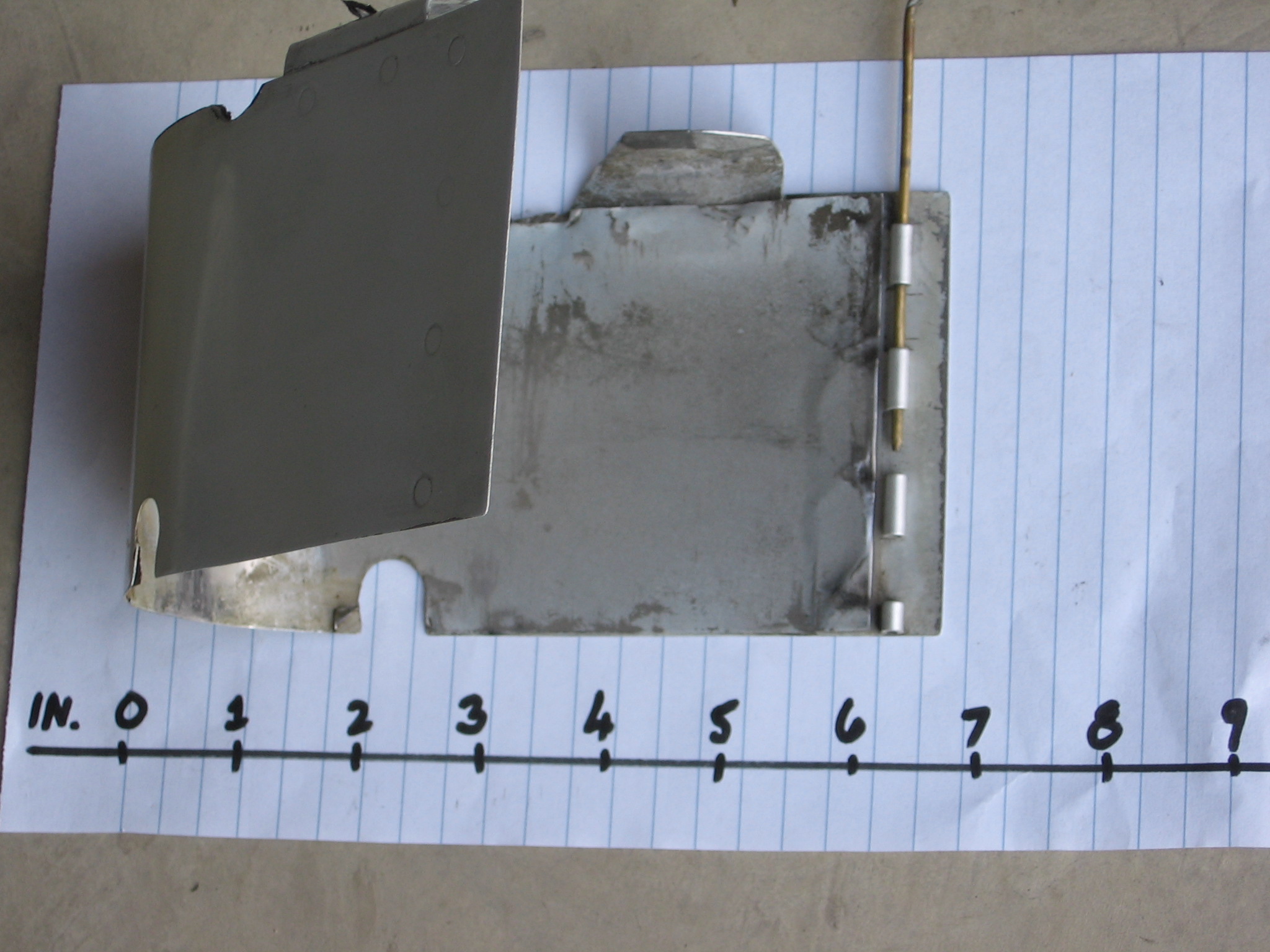

The next picture shows the lower part of the fairing.

The sharp bottom lip is covered by spliced nylon tubing so that it

does not damage the nose wheel fairing. The lower

piece is held in place by the tow bar tube of the nose gear.

The wire holds the

back part of the piece together via a piano hinge.

Finally, the upper piece. It has two tabs that overlap when the fairing

is held together with the wire. The spring-loaded telescopic

tube pushes against those tabs to keep the upper

piece snug against the bearing of the nose gear.

The fairing was designed after we had added the tube for the

tow bar. When planned at the same time, the tow bar attachment

should be low enough on the nose gear tube so that the two cutouts shown

in the picture are not needed.